Old Money Aesthetic Wardrobe ∥ Guide to Luxury Linen – 10 Elite Techniques, 8 Top Brands & 5 Linen-Like Fiber Types Explained

Summer has arrived, and alongside mulberry silk, linen is one of the most frequently discussed fabrics. The inspiration for this article came from my recent purchase of Gabriela Hearst linen corduroy flare pants. After wearing them for just one day, I discovered why Gabriela Hearst no longer makes corduroy from linen-cotton blends—linen is too stiff. Corduroy fabric is already somewhat rough and durable by nature, and after a full day of wear, it chafed the inside of my thighs. No wonder their new corduroy pieces are now made from softer cashmere materials.

This experience sparked my curiosity about the characteristics of current linen fabrics and the textile technologies and processes that can make linen softer. Additionally, I had never written about linen before, and we only started purchasing linen garments last summer.

We now have several linen pieces in our wardrobe, so I've decided to write this comprehensive guide covering the differences between linen and other hemp fabrics, excellent linen pieces from top brands, and comparisons of linen craftsmanship and quality.

01

Regardless of the type of hemp fiber, all hemp materials maintain a dry surface even after absorbing moisture. They expand significantly when wet and release heat, making them ideal for summer wear as they absorb sweat and dissipate heat effectively.

Beyond moisture-wicking properties, all hemp fabrics generally have limited stretch and flexibility, creating a somewhat dry feel. The photographs below of two 100% linen garments clearly demonstrate this characteristic dryness of the fabric.

Let me provide detailed distinctions between common hemp fabric types.

The most common hemp fabrics used in clothing are Hemp and Flax (linen). Linen is finer than hemp with better luster and superior breathability.

Although hemp fabric feels rough initially, it becomes softer with wear over time, especially after the fibers begin to break down. I own a pair of socks made from 80% hemp that I wore throughout last summer. You can see some fibers have broken down and become fuzzy, but the more they broke down, the softer they became.In comparison, the 100% linen socks purchased at the same time have also softened slightly, but not as noticeably as the hemp ones. They also show fewer broken fibers than the hemp socks. This contrast indirectly suggests that linen, with its higher cellulose content, is more resistant to wear.

However, for moisture-wicking and odor control, mulberry silk socks are superior, though they lack durability and are unsuitable for outdoor activities.

Possibly due to its medicinal properties, even non-psychoactive industrial hemp exhibits excellent antibacterial qualities and pest resistance. This is why hemp fiber shows "very low impact" in the Environmental Impact statistics table above.

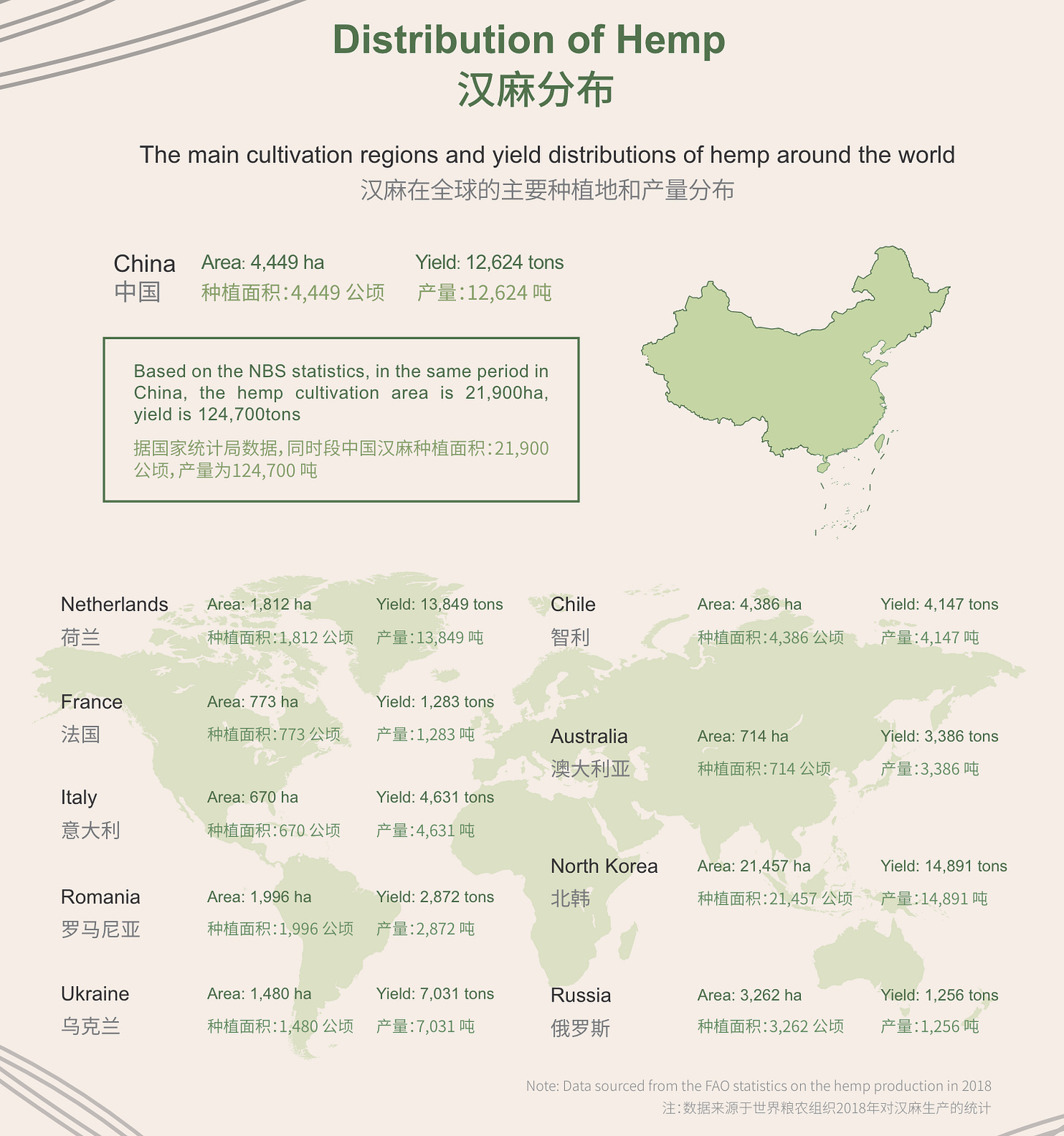

Global hemp production regions: The Netherlands leads (which explains why cannabis is legal there), followed closely by China (Heilongjiang and Yunnan regions) and North Korea as the top three producers. Production in Ukraine and Italy has decreased by nearly half.

Jute is an annual herbaceous plant growing in subtropical and tropical regions, with India as the primary producer. Jute fibers are particularly short and difficult to spin into yarn. High lignin content makes them rough and hard with poor flexibility, while low cellulose content makes them less durable than linen or hemp. Jute is typically used for packaging bags for bulk commodities like sugar and coffee beans, carpet backing, and famously in Muji's jute bags.

Another application for jute is in espadrilles as sole material. Luxury menswear and womenswear brands have been incorporating these in recent years, including Zegna, Thom Browne, and Gianvito Rossi.

Apocynum venetum, also known as wild hemp or tea leaf flower, has leaves that can be processed into tea (Apocynum tea) with blood pressure-lowering properties. This wild plant fiber is salt and alkali-resistant, suitable for growth in deserts or saline-alkaline soil, first discovered in the Lop Plain where Lop Nor is located. Due to high cellulose content (poor durability), high lignin content (too hard), fine fiber diameter (irritating to skin), and high pectin content (difficult to process), it's rarely used in clothing.

Ramie is China's indigenous hemp, produced in the Yangtze River basin. Ancient Chinese commoners wore hemp clothing because its particularly long fibers made it easy for household textile production. However, the fiber cells are extremely rough and irritating to skin.

Under microscope examination, ramie fiber cross-sections are larger and flatter (2-3 times larger than linen fiber cells). Insufficient fiber fineness makes it irritating to skin, while longitudinal sections appear bark-like, resulting in roughness and lack of luster (left image third row Ramie, right image sample C).

Linen longitudinal sections are very smooth, giving it the strongest luster among all hemp fabrics. Its diameter is typically smaller with uniform consistency, and fiber bundles are clearly visible. Cross-sections are predominantly pentagonal or polygonal with small, regular cavities (left image first row Flax, right image sample A).

Now let's analyze how the botanical terminology mentioned above affects fabric properties:

Cellulose content affects hemp fabric durability. From highest to lowest cellulose content: Linen > Hemp > Ramie > Jute > Apocynum venetum. Therefore, linen and hemp are more durable.

Hemicellulose links cellulose and lignin, affecting flexibility and biodegradability of hemp fabrics. Most hemp fabrics contain 12-18% hemicellulose, indicating generally low flexibility with minimal variation. Hemp's hemicellulose content ranges from 5.5-16.1%, showing significant quality variation in flexibility. Hemp fiber cross-sections naturally exhibit various shapes including triangular, oblong, kidney-shaped, and other irregular forms.

Pectin connects individual fiber cells. Apocynum venetum has exceptionally high pectin content, making fibers extremely difficult to process. Other hemp fabrics have similar pectin levels.

Lignin functions opposite to hemicellulose, providing structural support and UV protection. Higher lignin content reduces flexibility and increases hardness while enhancing UV resistance (jute, Apocynum venetum). Lower lignin content increases flexibility. Linen, ramie, and hemp used for clothing all have very low lignin content (below 5%), while Xinjiang Apocynum venetum and Indian jute have excessively high lignin content (these two hemp types also have high cellulose and low durability), making them too hard and suitable only for carpets and packaging bags, not clothing. Paradoxically, jute and Apocynum venetum are both harder and less durable, which is why they're rarely used in garments.

Some promote hemp over linen and ramie for sun protection due to higher lignin content, but jute bags would offer even better UV protection with a 10% difference, so such claims are typically misleading. In the chart below, lower trend lines indicate greater UV filtration.

Single fiber fineness affects comfort. Ramie has the coarsest fiber fineness at 30-40 micrometers, making it the most irritating fabric. The yarn is hard with a rough hand feel. For skin comfort, fiber fineness should be within 18 micrometers, which is why ramie clothing is rarely seen. Ancient Chinese commoners wore this rough ramie, which explains why people later preferred cotton over ramie. "Wearing sackcloth and mourning" also refers to this ramie fabric. Ramie is indigenous to China with distinct Chinese cultural characteristics. Ancient textile technology was traditional, and ramie's long fiber length made it relatively easy to weave at home, suitable for the self-sufficient small-scale agricultural economy of ancient China.

Among these fabrics, linen has the finest fibers. Linen's fiber fineness range is comparable to cashmere, making it non-irritating to skin. High-quality linen also has luster, and with low lignin content, it offers better stretch and flexibility compared to other hemp fabrics, plus excellent moisture absorption and durability. Therefore, linen is most commonly used in clothing textiles and is considered the premium hemp fabric among those discussed here.

Linen is classified into fiber-type, oil-type (the strange-tasting linseed oil), and dual-purpose varieties, all annual herbaceous plants. China's main production area is Heilongjiang (80% of domestic linen). Global linen production centers are in northwestern France, Belgium, southern Netherlands, Ireland, and Canada. Linen requires cool, humid climate for growth. Due to its wearability and Western European origins, linen carries Western cultural significance. The West first used linen for wound dressing, and Christianity used linen to wrap religious artifacts.

02

When discussing hemp, the default reference is to flax linen. Chinese hemp has been widely used in Chinese clothing in recent years. Among the 50+ brands I've written about, only Malo features the word "hemp." As for ramie, I've never seen any brand use it for clothing—it's too coarse and scratchy. The even more niche and rough jute and apocynum are not worth mentioning.

When it comes to 100% linen garments, what comes to mind? Isn't it easy wrinkling, dryness, stiffness, slub yarn knots, and irregular horizontal and vertical textures? Whether it's tops or bottoms, the silhouettes tend to be rather loose and flowing.

This section first introduces the types of 100% linen fabrics from various brands, followed by linen blended with other materials. The covered brands include Gabriela Hearst, Khaite, The Row, Kiton, Zegna, Akris, Agnona, and Isaia—all leaning toward suiting or minimalist styles. I've written about these brands before, so you can search my Substack homepage for extended reading.

aloe linen

Only Gabriela Hearst produces aloe linen. Most of their linen is treated with aloe, with only a small portion being regular linen. This treatment technology is currently only available in Italy. Julia Jentzsch mentioned aloe linen but only as an introduction—I haven't seen any actual clothing production. It seems unsustainable. I write about this brand somewhat as a negative fashion case study, as eco-friendly fabric manufacturing marketing is quite typical.

Aloe linen incorporates aloe vera extract through specialized processes (such as microcapsule technology) embedded into the fiber surface or yarn, forming a functional coating. This coating soothes and softens the linen fibers. Sometimes this is called "Aloe Vera Finishing" or "Aloe Infused Fabric." Since the aloe components are in coating or microcapsule form, frequent washing may gradually reduce their functionality.

Both dresses are 100% aloe linen. Gabriela Hearst uses pure linen fabrics for summer styles, while the same silhouettes are made in cashmere for winter.

Both pieces are Gabriela Hearst 100% linen. The left is regular linen, the right is aloe linen. The aloe-treated fabric clearly has a smoother texture.

The blue shirt is regular linen, more wrinkled and rumpled—the most common basic linen found in various mid-to-low-end brands. The pink piece below is aloe-softened linen. Despite the same fabric weight, it's smoother and softer, with a polished, silky fineness and more lustrous feel, making it more skin-friendly compared to untreated linen.

Some of Gabriela Hearst's linen is regular linen, with texture details as shown below—rough, dry granular texture that looks uncomfortable, like rural burlap sacks. I suspect my corduroy pants use this type of coarse linen.

This rough, primitive pure linen can only be worn in looser silhouettes. Too tight and skin-hugging, it chafes the skin. I have sensitive skin and only wear cashmere and mulberry silk, so Eddy mostly buys the linen garments. I only have one or two pairs of linen socks.

Gabriela Hearst also created an artistic piece using 100% linen, adding mulberry silk chiffon and wool drape fabrics to the naturally slubbed linen garment. However, this set only comes in one size and is an experimental new style. From the photos, this linen may have been aloe-treated, appearing softer.

denim linen

Denim linen uses 100% linen or 60% cotton + 40% linen or 89% linen + 9% wool to imitate denim fabric with twill weaving, including mimicking denim colors and twill knitting. Since denim, like corduroy, uses twill weaving and belongs to durable, stiff fabrics, it's not suitable for tight fits. Otherwise, like my pair, it initially chafed the inner thigh skin red and needed multiple wears and washes to soften, requiring a break-in period.

The Row uses 100% linen for denim linen, showing the irregular texture and slubs of linen fabric. The Row's supply chain typically uses Italian factories, but denim is produced in Japan because Japanese denim factories are indeed the most renowned globally.

The Nesson shirt also uses denim linen fabric. Because twill denim weaving is denser, the fabric has more structure and is flatter, without the obvious wrinkles of Gabriela Hearst's regular thin linen shirts.

Another brand with 100% linen denim weaving is Zegna. This series has a specific name: Oasi Lino fabric, clearly stating that all linen comes from local Europe. The series includes all of Zegna's local linen collections, not just the denim linen fabric mentioned here. I'll introduce this separately below.

This weaving technique differs from The Row's, similar to Agnona's batavia weave linen and Akris's double face linen. These three linen techniques are all similar to suiting wool—very structured, with tight, smooth fabric. I'll introduce these two distinctive linen types separately below.

Detail shots of The Row and Zegna's 100% linen denim fabrics, both showing twill weaving. Regardless of the material—even cashmere—this twill weaving creates a tighter, more durable, and structured feel.

Following the denim linen topic, I'll also discuss non-pure linen fabrics. After all, denim is a large category, so I'll include it in this pure linen section.

Isaia's denim linen is 89% linen, 9% wool, 4% silk, giving it more wool's drape and dimensionality plus silk's luster—smoother and more formal. Because this fabric is made thin, compared to The Row and Zegna's all-linen denim, it has more slubs.

Gabriela Hearst reduces the linen proportion to 38%, with the remaining 62% being cotton. Therefore, linen's texture primarily adds decorative irregular patterns and some moisture-wicking properties, with the visual texture leaning more toward everyday cotton feel.

Gabriela Hearst also has a washed skirt with cotton increased to 68%, more like regular cotton. The hemp used in these blends is probably regular hemp, not the brand's signature aloe linen—otherwise, the description should specify.

Zegna's 69% cotton + 21% linen trousers are completely indistinguishable visually.

These two from Zegna: left is 73% cotton + 27% linen, right is 80% cotton + 20% linen. Both look like cotton denim from the photos. When worn, you should feel some of linen's dry, sweat-absorbing properties.

double face linen | Batavia linen

Double face linen and Batavia linen might be different names used by Akris and Agnona, as both are pure linen fabrics that are structured and substantial like suiting wool, so I'll discuss them together.

Akris's double face linen fabric can make pure linen coats and jackets—this is my first time seeing this. Even Gabriela Hearst and Kiton need to blend 40% silk or cashmere when making linen suits, yet Akris has pure linen versions.

The fabric details are shown below. Akris's linen selection should be excellent. Previously mentioned linen fiber fineness ranges from 12-17; theirs should be premium quality. Notice there are hardly any slubs—particularly fine, even softer and more refined than Gabriela Hearst's aloe-treated linen.

Double face 100% linen tailored trousers have the same smooth silhouette as 100% wool. If you've read Gabriela Hearst Core Trouser Styles Analysis, you'll notice Gabriela Hearst and Akris have similar silhouettes.

Double face linen also makes jackets. Akris women's blazers and parkas are brand specialties, rarely seen in other brands.

Agnona's Batavia linen, compared to Akris, lacks Akris's fineness but still maintains structure and certain crispness.

During Dutch colonial times, "Batavia" was present-day Jakarta, Indonesia. Due to its historical trading position, Batavia was used to name various goods. In the textile industry, Batavia weave is a variant of twill organization with certain luster and strength, used for premium fabrics or linings.

Left image shows Agnona Batavia Linen dress, right shows The Row regular pure linen dress. Without comparing to Akris's overly refined 100% linen fabric, compared to regular linen fabric, Agnona is still more refined, flat, and substantial with fewer slubs.

light linen

Light linen is the opposite of the refined, substantial double face linen and Batavia linen above—lightweight, with obvious slubs and texture, belonging to the most common standard linen fabric. Of course, quality varies. Higher quality has stronger luster, more fineness, and fewer slubs. Among the lightweight linens organized in this section, Kiton's pure linen fabric clearly has superior quality, better than Zegna and Agnona.

From left to right: Kiton, Agnona, Zegna. You can see Zegna has the most wrinkles and is least smooth, representing entry-level linen.

Light linen comes from Agnona's naming. This Agnona linen has good quality, with acceptable smoothness and refinement, capable of creating silhouettes.

Every major brand has quality tiers. Akris's linen categories also have high and low distinctions. Besides the double face linen above, they also have more ordinary categories with slubs, texture, wrinkles, and loose drape.

Kiton also has entry-level linen and more expensive premium refined linen. This Kiton women's 100% linen dress shows great quality feel with moderate wrinkling.

The shirt and men's trousers below use more basic, entry-level linen quality—dry with many wrinkles.

Comparable to these Zegna shirt fabric qualities. Actually, this texture quality linen is quite good. Compared to the Gabriela Hearst and The Row American brands mentioned earlier, these old-money Italian brands still excel in craftsmanship and fabrics, though the American brands have stronger design capabilities.

Comparing Zegna's already wrinkled linen fabric with Sunspel and lower-end James Perse shows that Zegna's is quite good.

Sunspel is superior to James Perse. Except for James Perse's Lotus jersey cotton tees, I don't recommend their other items. The cheap light linen is the three James Perse pieces on the left in the second row—very coarse.

Gabriela Hearst's aloe linen-treated suit also belongs to mid-tier quality, with a gap compared to these Italian brands.

If the eight brands mentioned in this article are too high-end, for beginners, I recommend Sunspel, Paul Smith, Aspesi, and Oliver Spencer—these London luxury menswear brands. Although their linen quality has some differences from Kiton and Zegna's cheaper entry-level options, they're adequate for linen fabric beginners.

Eddy's two pure linen pieces are Oliver Spencer tartan coarse linen and Paul Smith's finer linen.

We also have a half-cotton, half-linen navy Cos men's trousers and my off-white half-silk, half-linen trousers. The texture is as shown in the photos. Cotton-linen blends feel stuffy, thick, and dry due to the cotton. Half-silk is fine, smooth, and lustrous. Pure linen doesn't feel stuffy—even if not the best linen, despite being dry with slubs, the fabric is cool. Therefore, I don't recommend cotton-linen blends. Like the denim linen mentioned earlier, avoid any linen blended with cotton—the quality is too low.

After seeing mid-to-low-end linen quality, looking back at these two pure linen Zegna trousers reveals what good linen garment texture looks like.

03

This section introduces linen blend fabrics. Besides the aloe coating and premium finest linen fabrics mentioned in section 02, another way to make linen garments comfortable is to blend in one-third mulberry silk or cashmere. Below is a summary organized by different blended fabric techniques.

jersey linen

Jersey was already introduced in James Perse as a knitting technique that creates softer fabrics. I first encountered jersey linen at Agnona, not seen in other brands, because Agnona is the only cashmere brand among these 8 brands and emphasizes knitting. Previously when writing about Mulberry Silk Plissé and Its Difference from Pleats, Agnona's Plissé also combined their signature knitting techniques.

Agnona Jersey Linen is 70% linen 30% mulberry silk. Comparing Jersey knitting with the second row's Zegna woven 100% linen and Isaia woven 60% mulberry silk + 40% linen demonstrates Jersey's softness.

Through Isaia, you can see that higher silk content significantly increases luster and smoothness.

mesh linen

Different proportions of mulberry silk and linen blends are most distinctively featured in Khaite Dress. These mesh linen open-weave fabrics are very popular this year. Brunello Cucinelli and Gabriela Hearst mainly use cashmere fabrics for this technique, while Khaite excels more with mulberry silk and other summer fabrics.

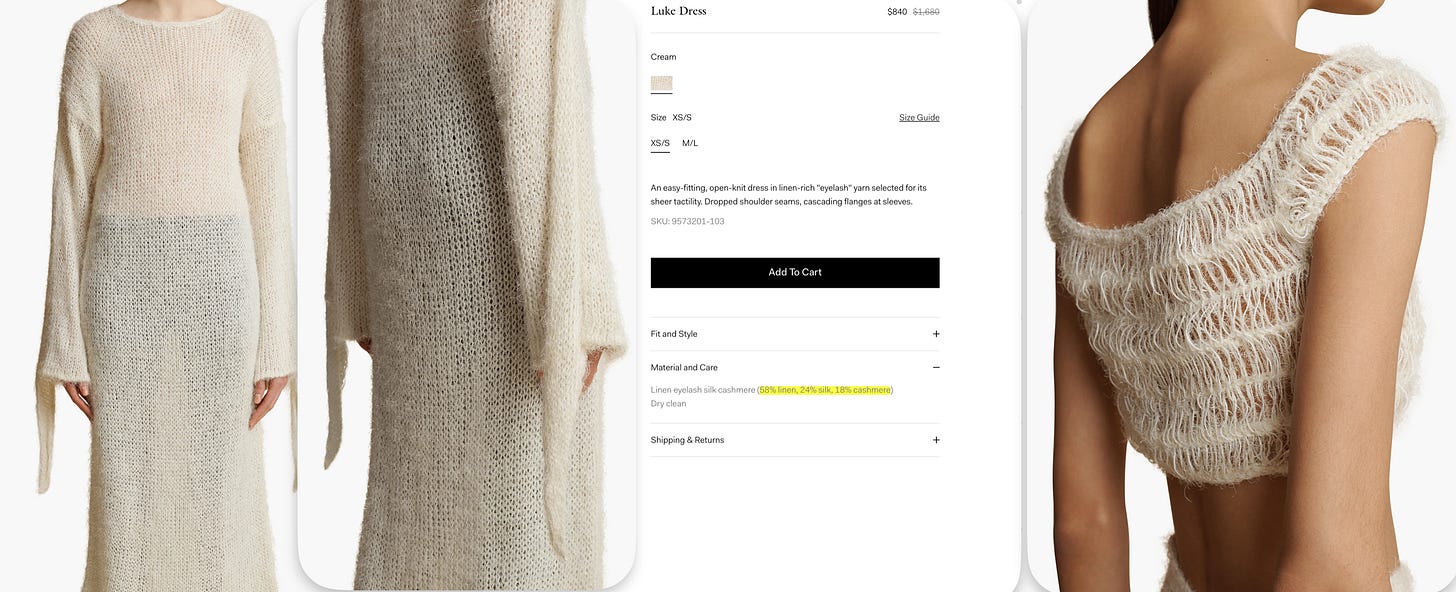

Both pieces below are 58% linen, 22% mulberry silk, and 18% cashmere. Because of the large open-mesh weaving technique, these aren't the flat woven silk-linen blend fabrics we commonly think of.

gauze linen

Currently, I've only seen gauze linen at Khaite. Gauze refers to semi-transparent, soft gauze fabrics. The most common gauze is pure mulberry silk, such as organza and chiffon, which are types of gauze.

These two dresses below are made from 68% linen, 17% mulberry silk, 15% polyester. Without looking at the fabric label, I would have thought they were 100% mulberry silk.

Because linen has limited stretch and tends to be stiff, mulberry silk is too fragile, and gauze knitting itself is too lightweight, polyester fiber was added for stability.

As a forward-thinking creative design brand focused on fabrics, Khaite emphasizes dresses and leather garments, so basic pieces are rare. Their linen fabrics only include the mesh weaving and gauze types mentioned above.

wool silk with linen

Gabriela Hearst's signature suiting fabric: 49% wool + 30% mulberry silk + 21% linen, combining wool's drape and structure, silk's luster, and linen's texture and moisture-wicking properties. The proportions are very well balanced. This fabric is used in Gabriela Hearst's core silhouettes: the Angela blazer and Vesta slightly flared trousers.

Gabriela Hearst's 49% wool + 30% mulberry silk + 21% linen looks much better than Akris's simple wool + linen blend. Silk's luster significantly elevates the texture, especially when linen fabric is typically ordinary.

Adding wool makes more silhouettes possible.

cashmere linen

Kiton's summer high-end suiting likes to use half-proportion cashmere blended with linen. Because Kiton's linen quality is the finest, with excellent luster and fineness, it doesn't need much mulberry silk to achieve lustrous texture.

The fabric proportion is 47% CASHMERE 45% LINEN 8% SILK. At first glance, I thought it was linen + wool, but it's actually 47% cashmere.

Under specific lighting, you can also see the fluffy luster of premium cashmere.

others

Linen blended with synthetic fibers and cotton is typically used in The Row's low-end entry-level pieces. BC has also started cost-cutting in recent years, using synthetic fibers for entry-level non-core styles.

I don't like linen-cotton blends, let alone synthetic fibers.

These American minimalist brands and Italian-French major capital brands like using synthetic fibers to reduce costs, showing no principles. Zegna uses such fabrics only for shoes.

Espadrilles have been really popular these years. Just mentioned in Pedro García a few days ago, now even Zegna men's shoes are starting to make jute braided styles.

Speaking of Akris, this jacket is half linen, half polyurethane (synthetic faux leather). Looking closely at the fabric, you'd think it's leather, but seeing the sleeve wrinkles from a distance reveals the linen fabric.

I don't recommend cotton + polyester fiber blends exceeding 25%, even from high-end brands like Akris and Kiton.

Epilogue

Before concluding, look at these few pieces from Adam Lippes .You'll realize that even after reading this entire article, or even if you're already a fabric expert, sometimes you can't accurately guess fabric composition when encountering garments blindly.

This gray piece has the silhouette of superfine wool with some linen texture, but who would know it's 98% cashmere?

This knit piece looks like cotton + mohair, but it's actually 100% mulberry silk.

So, even with extensive fabric and clothing knowledge, with today's textile technology where various fabrics can mimic others, even fabric experts are sometimes puzzled. This is when you must trust brands—you need reliable brands. That's why all my content covers legitimate international major brands with physical stores and history.

WeChat: pamperherself